Welcome to ZHENGXI hydrualic!

PROCESS

-

4 Column Composites Molding Hydrualic Press Machine For SMC/BMC/GMT

Common composite materials include : SMC BMC FRP etc.

넶340 ¥ 0.00 -

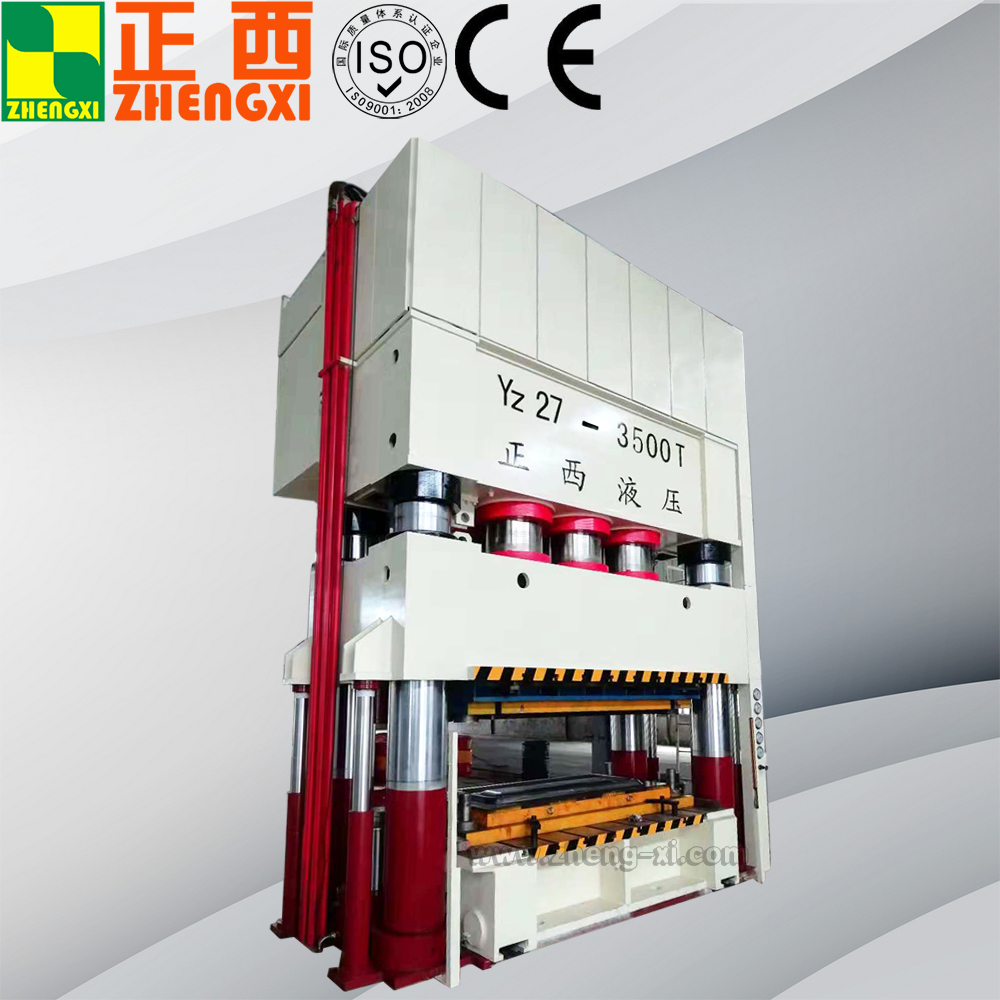

4 Column 3500 Ton Metal Deep Drawing Hydrualic Press Machine For Sheet Metal

ZHENGXI thick metal plate deep drawing press also called metal forming press,hydraulic deep drawing press, it is widely used for metal deep drawing,stamping.

넶550 ¥ 0.00 -

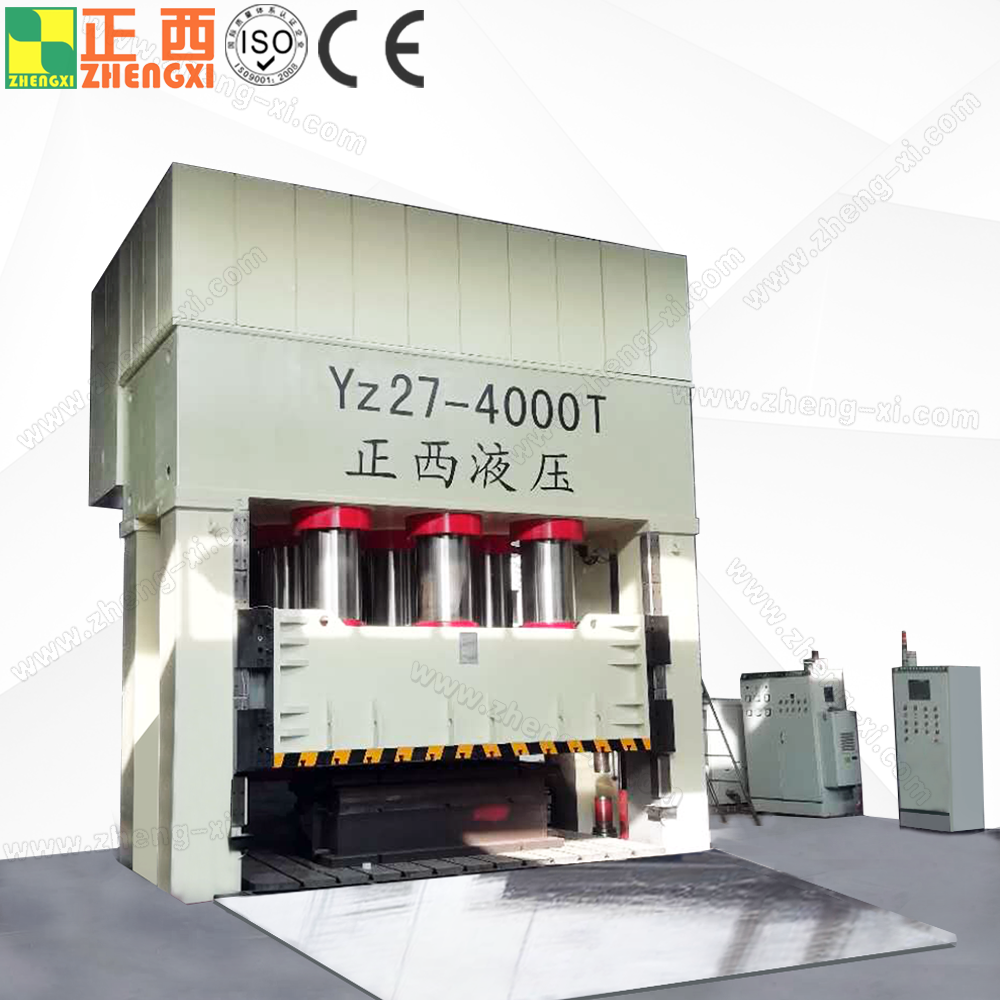

H Frame 4000 Ton Metal Deep Drawing Hydrualic Press Machine For Thick Metal Plate

ZHENGXI thick metal plate deep drawing press also called metal forming press,hydraulic deep drawing press.

넶746 ¥ 0.00 -

H Frame Composites Molding Hydrualic Press Machine Hydraulic SMC Moulding Press

H frame Composites Molding Press is equipped with 4 side or X type guiding system using bronze & graphite guiding platen.

넶347 ¥ 0.00

HOT PRODUCTS

LATEST NEWS

Using FULL CAD Drawing,

2D or 3D design of the high quality press

that meets specifications approval

requirements by customers

Cutting (CNC automatic cutting)

by the 2D CAD Drawing Layout

that is designed according to specifications

approved by customers

Perform the grinding work and remove

elements hindering the operations, scale, slag

and other welding by using

the specified welding rod (CO2 WIRE)

Improved the reduction of residual stress

and material quality of the welding section

by the annealing (heat treatment)

Operation to remove the mill scale and

impurities on the surface for

the high quality of the press (AIR SHOT BLAST)

Perform process operations in accordance

with materials, dimensions, tolerances,

and illumination specified in the design

specifications. (CNC BORING, PLANER)

Foreign Image enhancement and

product quality improvement by performing

the plumbing, wiring, assembly, test operation

and paint job according to specifications

Packaging operations in preparation

for the damage, waterproof, moisture-proof,

theft, loss, temperature, and corrosion

by the impact of the product

Deliver products by dispatching

appropriate transportation vehicles

after checking the block-specific

weight of press products.

Perform the plumbing, wiring, assembly

and operation during the installation

according to specifications in order to provide

the high quality press to the customer

Our company maximizes the use of national and industry standards, strictly control each process, guarantee the quality of each component. After the equipment is slod to our customer, we will do a full set of survey about the performance of our equipment, then improve our technology and quality. We also got the ISO9001:2008 and CE certificate. The company is the largest and with complete machining process in the Sichuan province.

CONTACT US

Copyright Chengdu Zhengxi Hydraulic Equipment Manufacturing Co.,Ltd

SEND US AN INQUIRY